Why do I need Bleeds? What are they for? When do I need to add bleeds to a Project?

Bleeds, simply enough, are an added boarder of a project, extending out past the printing area. This bleed area is then cut off and discarded. No one who receives a your finished project will ever sees the bleeds, but when printing many of cards at a time, bleeds are absolutely necessary.

Bleeds are a must have for any project where ink touches the edge of the paper. Here at Eagle we often print jobs in the hundreds or even thousands. These projects, are never cut 1 at a time, but are cut in bulk, in a large machine. Because of minor variations in the paper size, printer tolerances, and human error, we can never guarantee that a stack of identically printed items will align up correctly in the machine. This is where bleeds come in.

Having a bleed and a proper margin around the edge of your project ensures that, when cut, your project will have a clean look without any annoying white lines around the edges. If you have ever used a small cutter to make straight cuts by hand (example below) you know how hard it can be to line up multiple pages and have them come out with perfect edges every time.

Can I just make my piece larger to account for the bleed?

Simply put. No. Say you have a postcard, one that has text that goes nearly out to the edge of the page, and you make it a quarter inch larger, that text near the edge now has a chance to be cut off during the trimming process because enlarging the image sacrifices the safe margin between your copy and the trim line. Whatever distance you allocate for bleed you will also want to allocate the same (if not greater) distance for your margin.

Remember, Margin always goes with bleed. Bleed is what you extend beyond the trim line with the intention of it being cut off, so that your project comes out with a nice clean edge. Margin (you could think of it as your safety zone) is what you shrink away from the trim line to ensure your content it isn’t cut.

How do I add bleeds to an already completed project?

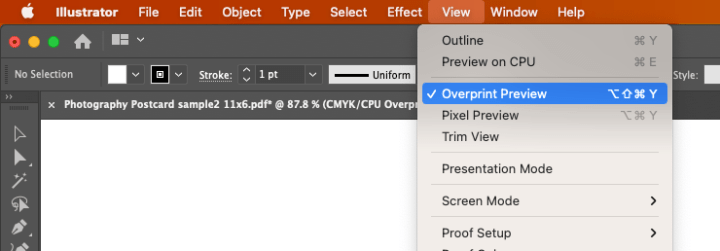

Many programs, such as InDesign have a setting built in for bleeds. These settings will vary depending on the program you use, but in general you want to make the canvas or workspace larger by adding a 1/8 in bleed around EVERY side of your project without moving the imagery you already have completed (1/8 inch for postcards and digital press. Double the bleed size – 1/4 inch – for web press & bound projects). Either add the bleed to the project in the settings or Increase the canvas size. Example: A 5×7 piece will have a final size of 5.25×7.25. Then simply expand all of your images and color that touches the edge of paper out past where you had it so that it completely fills the newly added bleed area. Then export your PDF with the bleeds turned on (if applicable), and check the final PDF to make sure it is the appropriate size before sending it over to Eagle for Print.

When do I need bleeds larger than 1/8 inch?

Larger projects such as magazines and calendars may need a larger bleed when the project will need to be trimmed twice in production, once before binding, and once after so that the final product will have a nice even edge. Web Presses require a larger bleed because they print & fold inline at high speeds, thus requiring a slightly larger margin for movement. For these projects, increase the bleed size to 1/4 inch along with another 1/4 inch margin for EVERY side of your document (or add 1/2 inch total to the final dimensions in both directions.)

Click on the link Below to download Instructions on how to set up bleeds in an InDesign File.

PDF: Adding Bleeds to an InDesign File.

And that’s it. With your bleeds set up and exported correctly your project should come out just as great as you envisioned.

Happy printing and thank you for working with Eagle.